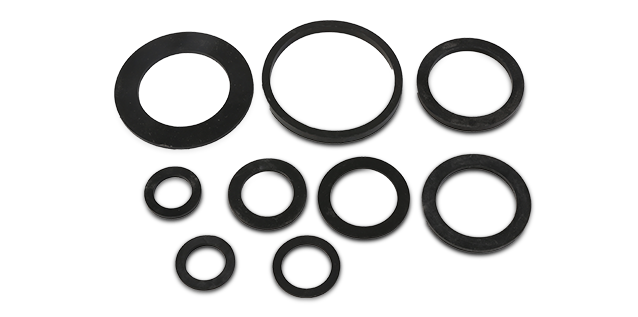

Professional rubber o ring seals are essential components used in a wide range of industrial applications to provide efficient sealing solutions. These small yet powerful devices play a significant role in ensuring the reliability and integrity of various systems. In this article, we will delve into the numerous ways Professional rubber o ring seals contribute to industrial efficiency and effectiveness.

1. Preventing Leaks:

Professional rubber o ring seals are designed to create a tight and reliable seal between two mating surfaces. Their circular shape, made from high-quality rubber materials, allows them to fit precisely into a groove or a gland. When compressed between the surfaces, the O ring creates a barrier that prevents the escape of fluids, gases, or other substances. This seal ensures that no leaks occur, minimizing the risk of contamination and preserving the integrity of the system.

2. Chemical Resistance:

Professional rubber o ring seals are available in a variety of materials, including nitrile rubber, silicone rubber, and fluoroelastomers. Each material offers different levels of chemical resistance, allowing O rings to be used in diverse industrial applications. For example, nitrile rubber O rings are commonly used in industries such as automotive and oil and gas, as they exhibit excellent resistance to oil, fuel, and hydraulic fluids. In contrast, fluoroelastomer O rings are highly resistant to harsh chemicals, acids, and high temperatures, making them suitable for applications in the chemical and pharmaceutical industries.

3. Temperature and Pressure Resistance:

Professional rubber o ring seals are designed to withstand a wide range of temperatures and pressures, making them versatile components for challenging industrial environments. Whether exposed to bad hot or cold conditions, rubber O rings maintain their sealing capabilities without losing their elasticity or shape. This enables them to effectively seal systems, even in demanding applications such as high-pressure hydraulic systems or cryogenic industries.

4. Longevity and Durability:

Professional rubber o ring seals are known for their longevity and durability. When designed and installed correctly, they can provide reliable sealing for extended periods, reducing the need for frequent replacements or maintenance. The quality of the rubber material used in O rings significantly influences their lifespan. Additionally, the compatibility of the O ring material with the substances it comes into contact with is crucial in determining its durability. Regular inspections and proper maintenance help ensure that the O rings continue to perform better over time..jpg?imageView2/2/format/jp2)

5. Versatility in Applications:

Professional rubber o ring seals find utility in a vast array of industrial applications. They are used in hydraulic and pneumatic systems, pumps, valves, pipe connections, and fittings, among others. These versatile sealing solutions can accommodate various sizes and shapes and are compatible with a wide range of substances. This adaptability allows rubber O rings to be employed in every industry, including automotive, aerospace, manufacturing, and electronics.

Conclusion:

Professional rubber o ring seals play a pivotal role in ensuring the reliability, efficiency, and safety of industrial applications. Their ability to prevent leaks, resist chemicals, withstand high temperatures and pressures, and exhibit longevity and durability makes them valuable sealing solutions. As industries continue to advance, the importance of Professional rubber o ring seals in maintaining industrial reliability will only grow, emphasizing the significance of these small but powerful components

English

English-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

-2.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)