Rubber and plastic are both synthetic materials that are widely used in manufacturing due to their versatility, durability, and low cost. However, there are some important differences between these two materials in terms of their properties, uses, and manufacturing processes.

One of the main differences between rubber and plastic is their chemical composition. Rubber is a natural polymer that is derived from the sap of rubber trees, while plastic is made from synthetic or semi-synthetic polymers that are derived from petrochemicals.

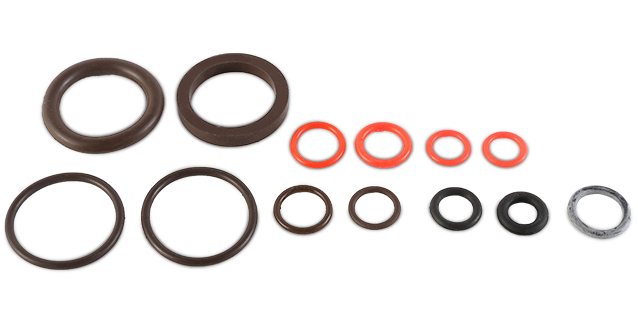

Another key difference is their flexibility and elasticity. Rubber is known for its elasticity and ability to return to its original shape after being stretched or compressed, while plastic is generally less elastic and more rigid. This makes rubber a popular choice for applications that require sealing, cushioning, or vibration resistance.

Rubber and plastic also have different temperature and chemical resistance properties. Rubber is generally more resistant to high temperatures and chemicals than plastic, making it a popular choice for applications in industries such as automotive and aerospace. Plastic, on the other hand, is often used in applications that require water resistance, such as packaging and consumer goods.

In terms of manufacturing processes, rubber is typically formed through a process called vulcanization, which involves heating natural rubber with sulfur to increase its strength and elasticity. Plastic, on the other hand, is produced through a variety of methods such as extrusion, injection molding, and blow molding, which involve melting and shaping the polymer material into the desired form.

What properties of rubber and plastic make them suitable for different applications?

Rubber and plastic are versatile materials that are used in a wide range of applications, from consumer products to industrial applications. The key properties of these materials that make them suitable for different applications include:

(1)Elasticity and Flexibility: Rubber is known for its elasticity and flexibility, which makes it suitable for applications that require cushioning, shock absorption, and vibration resistance. Plastic can also be flexible, but it is generally less elastic than rubber.

(2)Durability: Both rubber and plastic are durable materials that can withstand wear and tear, making them ideal for applications that require long-lasting performance, such as automotive parts and machinery components.

(3)Chemical Resistance: Rubber and plastic can be designed to resist exposure to chemicals, making them suitable for use in industries such as automotive, aerospace, and medical devices where exposure to harsh chemicals is common.

(4)Water Resistance: Plastic is particularly suited for applications that require water resistance, such as packaging, containers, and water pipes.

(5)Temperature Resistance: Rubber is known for its ability to withstand high temperatures, making it a popular choice for applications in industries such as automotive and aerospace. Plastic, on the other hand, can be designed to withstand low temperatures, making it suitable for use in refrigeration and freezer applications.

(6)Machinability: Both rubber and plastic can be machined and formed into complex shapes and designs, making them ideal for use in a wide range of products, from toys to medical devices.

(7)Cost: Both rubber and plastic are relatively inexpensive materials, which makes them attractive options for manufacturers who need to produce large quantities of products at a low cost.

English

English.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-5.jpg?imageView2/2/format/jp2)

-5.jpg?imageView2/2/format/jp2)

-6.jpg?imageView2/2/format/jp2)

-8.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)